01/12/2023

Facility managers and specifying engineers responsible for a plant or building’s cooling equipment operation can be at the mercy of vendors overstating the efficiency of their units. Over- or under-sized systems can cause efficiency losses, underperformance, processes being put at risk, or not meeting demand on a hot day.

Fortunately, there is an organization dating back to the 1950s of owner-operators, suppliers, and cooling tower manufacturers who are testing and certifying the quality and thermal performance of a manufacturer’s equipment is in accordance with its published ratings.

This article will explore the Cooling Technology Institute (CTI) Standard 201 (STD-201) Thermal Certification Program, share perspective from leading cooling tower manufacturers, and cover other existing and evolving CTI test codes, standards and certifications. This article will also emphasize the investment and bandwidth contributed to CTI by cooling tower manufacturers for the benefit of the industry and its end users.

Two Marley® cooling towers installed in St. Louis, Missouri. Image courtesy of SPX Cooling Tech, LLC.

Overview of Thermal Performance Testing & Certification

CTI Standard (STD) 201 certifies all models of a line of evaporative heat rejection equipment offered for sale by a specific manufacturer will perform thermally in accordance with their published ratings. STD-201 has two branches. First, STD-201RS is titled Performance Rating of Evaporative Heat Rejection Equipment, and covers testing, ratings and published data requirements. Secondly, STD-201OM is titled Operations Manual for Thermal Performance Certification of Evaporative Heat Rejection Equipment, and monitors compliance with the provisions of STD-201RS. [1]

“Before CTI certification, there was a tendency of vendors to overstate performance of their evaporative heat rejection equipment,” said Benjamin Cohen, Manager, Product Marketing – North America, Baltimore Aircoil Company. “Now, all cooling tower manufacturers are on a level playing field.”

The Licensed CTI Thermal Certification testing agencies are based in Tennessee, Kansas, Singapore and Germany. CTI’s global footprint complements its partnership with Eurovent, Europe’s industry association for HVAC, process cooling and food cold chain technologies.

Rooftop installation of an adiabatic fluid cooler overlooking Paris, France. Image courtesy of EVAPCO.

“Most often, representatives from CTI’s licensed agencies travel to the manufacturers’ site to conduct testing,” said Larry Burdick, Director of Technical Services, SPX Cooling Tech, LLC. Mr. Burdick serves as Committee Chair for ATC-105, the thermal test code published by CTI, and Committee Chair for ATC-128, the sound test code for heat rejection equipment.

Field testing can be conducted following CTI’s ATC-105 test procedures, however field performance testing a unit under STD-201 at an end user’s plant for example, is not practical at times. Challenges of testing at an end user site include providing adequate and stable heat duty for testing, interrupting processes, being in a remote location, properly calibrating flow meter readings and instrumentation, or obstructions around the tower. Therefore, testing at a cooling tower manufacturer’s dedicated sites using CTI owned and calibrated flow meters and test instrumentation is most common.

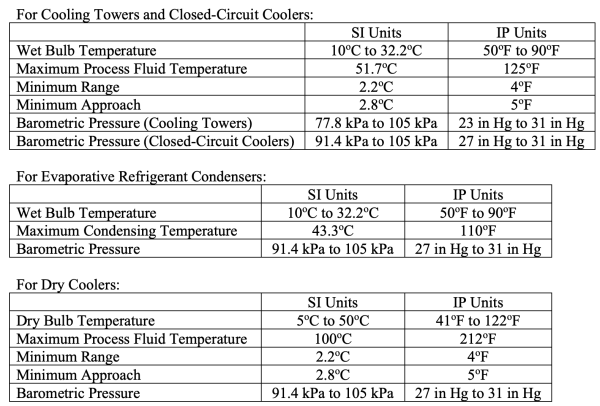

STD-201RS limits of certifications are outlined in Figure 1. Testing conditions must be set within these given parameters. As shown, limits of certification are different for cooling towers/closed circuit coolers, evaporative condensers and dry coolers.

Figure 1: CTI STD-201 Limits of Thermal Certification. Image courtesy of CTI.

- Wet bulb temperature (WBT) is defined as the temperature of adiabatic saturation. This is the temperature indicated by a moistened thermometer bulb exposed to the air flow.

- Approach temperature is the cold water temperature minus WBT. Due to cumulative instrument minimum measurement accuracies, anything less than the minimum approach results in a cumulative test error band that is outside of the allowable test tolerance of 5%.[1]

- Range is the hot water temperature minus the cooled water temperature. The minimum allowable instrumentation accuracy for temperature measurement is ±0.10°F (±0.05°C). [1]

- Barometric Pressure, or atmospheric pressure, is the pressure of the atmosphere usually expressed in terms of height of a column of mercury. Barometric pressure drops as altitude increases.

With over one hundred participating manufacturers in the Cooling Technology Institute, testing and certifying each of the tens of thousands of units coming off the production line is not feasible of course.

“We test and certify a unit from each product line in an OEM’s CTI-certified portfolio, but we’re also testing the OEM’s capability to accurately predict cooling capacities of their units,” said Mike Womack, the STD-201 Thermal Certification Administrator.

Once a product line is certified, participating cooling tower manufacturers must complete annual reverification tests for each applicable product line to remain involved in the program.

“Each year, a licensed CTI testing agency visits our labs and retests a unit from each of our cooling tower and fluid cooler lines,” said Natasha Rinehart, former CTI Board of Directors, and Manager – Fluid Coolers with EVAPCO. “We then update the Data of Record for our CTI-certified portfolio, 49-point disclosure tables and more. It’s an annual commitment to paying labor, program and testing fees to ensure customers have peace of mind when it comes to the thermal performance of our equipment.”

“It's a very worthwhile commitment,” echoed Jennifer Hamilton, Vice President of CTI, and Vice President – HVAC Product Development with EVAPCO. “Every time we launch a product, it’s another unit we must build and test every year. A significant amount of time in our labs is allocated to testing. Our organization has also invested in construction of additional testing labs. We pay a premium to ensure our equipment will perform as stated.”

Thermal Performance Reporting and Disclosure

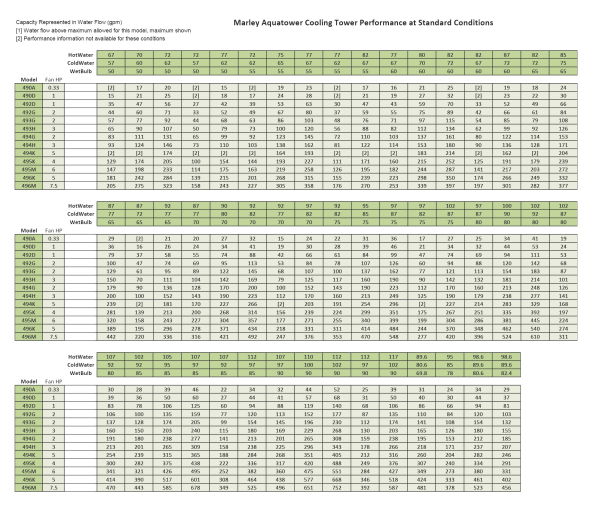

Published thermal ratings of STD-201RS certified cooling towers are available as standardized 49-point disclosure tables presenting the heat rejection capability and gallons per minute (GPM) at 49 different design conditions, or constant duty points, for different fan horsepower (HP) sizes in the product range. With reference to the 49-point table (Figure 2), end users and engineers can specify their design condition (hot water, cold water and wet bulb temperatures) and desired GPM, then the manufacturer selects the model size and HP requirement. The purchaser can then use the published data to verify their capacity can be met – before the sale is finalized. The standard design conditions from ASHRAE 90.1 Energy Standard for Buildings (except low-rise residential buildings) are 95°F hot water, 85°F cold water, 75°F wet bulb (35/29.5/23.9°C). ASHRAE 90.1 requires CTI certification of cooling towers and closed-circuit coolers on all new construction projects.

Figure 2: a 49-point cooling tower performance disclosure table for a crossflow cooling tower from a leading manufacturer. A plant manager operating their system at ASHRAE 90.1 standard design conditions (95/85/75°F) requiring 340 GPM for its processes, would select the 6 hp fan size model. Table courtesy of SPX Cooling Tech, LLC. Click to expand.

“In addition to 49-point tables, participating OEMs also share access to their own selection software with the Thermal Certification Administrator,” said Nick Mascarenhas, Vice Chair, STD-201 and Chief Engineer – Thermal Modeling with Baltimore Aircoil Company. By granting the Administrator access to the manufacturer’s selection software, the Administrator can verify the capabilities of the manufacturer to accurately predict cooling capacities of their units. Lastly, participating OEMs are required to share the Data of Record only with the Thermal Certification Administrator. This document covers full unit dimensions, air inlet surfaces, fan diameters, thermal performance, and all other component details. The Data of Record will also cover private labeling. Both the manufacturer and the private label brand are issued the same CTI Certification Validation Number for the same model unit.

Crossflow evaporative coolers at a Houston terminal used to reduce system power consumption and process temperatures. Image courtesy of Baltimore Aircoil Company.

New and Evolving Test Codes and Standards

In 2018, CTI adopted the test code ATC-105DS for dry coolers. As of March of 2022, STD-201 now includes dry cooler thermal performance in the certification standard, which previously only covered evaporative products.

.jpg)

Dry cooler principle of operation. Image courtesy of EVAPCO.

“Before 2018, there were no guidelines or regulations for testing dry coolers. Four years later, the prevalent certification standard STD-201 is now covering dry coolers – a big deal for the industry. Performance isn’t in question anymore. Dry coolers are now being considered for projects more and more as the world continues to change,” said Mihir Kalyani, Global Product Manager – Dry & Adiabatic Fluid Coolers, EVAPCO.

Jennifer Hamilton was the committee chair for development of this test code. “It took a few years to create this certification program. We had to revise STD-201 to include dry cooling, appoint a certification administrator, write a new license agreement, update the licensed test agency agreements, have a certification test agreement as well as a non-certification test agreement, advertise for participants, agree on a date of record and a lot of other work! We are really passionate about this program,” said Hamilton.

“Before, the only option for testing thermal performance of large installations of dry coolers was using a CTI test code in the field. At times, that is not feasible. Now, a customer can purchase multiple units knowing they’re coming straight from the factory, tested and CTI-certified, with no need for field testing,” said Natasha Rinehart, EVAPCO.

.jpg)

Multi-unit EVAPCO eco-Air dry cooler installation. Image courtesy of EVAPCO.

This year, CTI also launched its Product & Material Certification Program for open and closed-circuit cooling towers. The initial program will certify that fiber-reinforced pultruded (FRP) structural materials for use in cooling towers meet the material properties in Standard 137. STD-137 covers classification, materials, tolerances, defects, workmanship, inspection and the physical, mechanical and design properties of glass FRP structural shapes for use in construction items in cooling tower applications.

“This benefits the end user because they can feel confident while collecting bids knowing the equipment has been tested and certified,” said Frank Michell, Product & Material Certification Administrator.

Larry Burdick and Nick Mascarenhas also both shared an acceptance test code for adiabatic coolers is also being developed. Other test codes and standards CTI has or is developing include flow, drift emissions, plume abatement, sound and more.

Conclusion

Thermal certification of evaporative heat rejection equipment and dry coolers is helping end users and specifying engineers reduce the water and carbon footprint of their facilities, is preventing false performance claims and is helping improve uptime and reliability.

“Our organization is fully committed to CTI. We typically have representation on all task groups and committees. However, what’s most important is the collaborative effort with other manufacturers, suppliers and end users developing standards for the benefit of the industry and the end user,” said Scott Nevins, Vice Chair of the CTI Performance and Technology Committee and Director of HVAC, Cooling Tower Group with EVAPCO.

For similar article on cooling towers, please visit https://coolingbestpractices.com/technology/cooling-towers.

For more information about the Cooling Technology Institute, visit www.cti.org.

Citation

[1] Answers to Frequently Asked Questions for CTI STD-201 Thermal Certification of Evaporative and Air-Cooled Heat Rejection Equipment | https://assets.speakcdn.com/assets/2793/answersforfrequentlyaskedquestions.pdf,

[2] Cooling Technology Institute Website | www.cti.org.